EMS Service

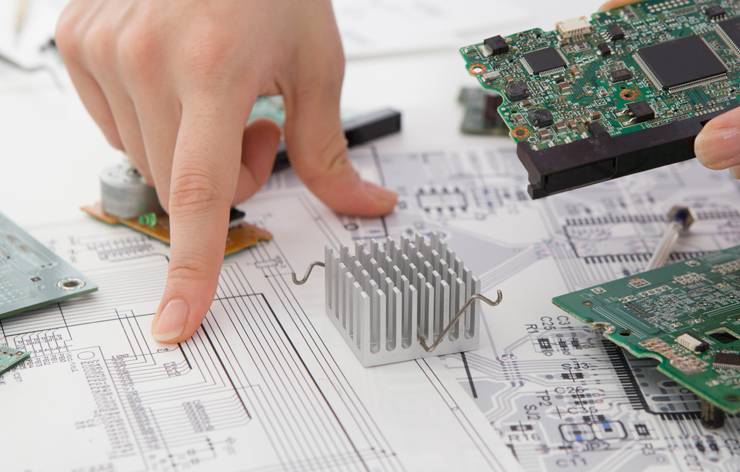

We develop and produce control electronics for numerous demanding industries and applications. So, we know from experience what is important in urgent prototypes and long-term series productions.

You can use our know-how, our production capacity, and our claim to deliver top performance with our EMS services.

We provide assistance across every phase of value generation

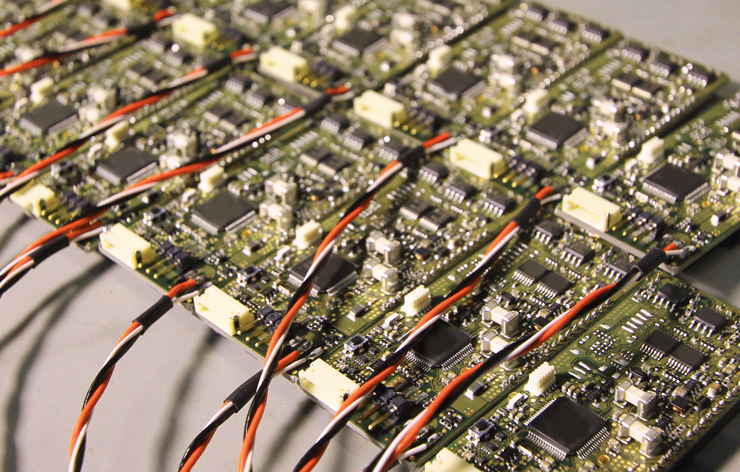

Serial production

Samples, Prototypes, Pre-series and Rush Orders

Services

Our Services in Detail

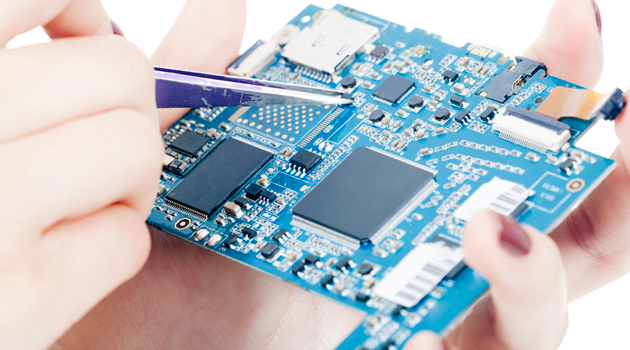

SMD Assembly

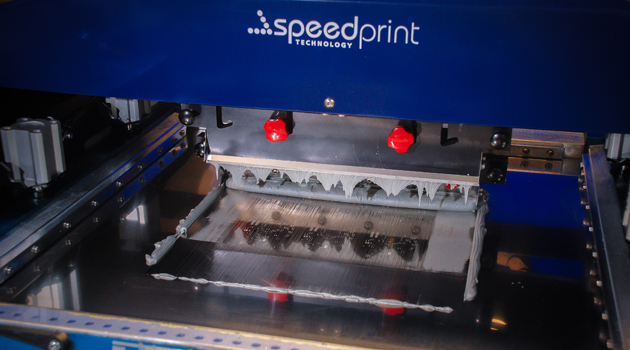

Solder Paste Printing

- Use of laser-cut stainless steel stencils from well-known German stencil suppliers

- Integrated stencil cleaning guarantees residue-free and consistent solder paste printing over the entire batch

- Automatic 2D inspection of the print for solder paste quantity as well as bridging before assembly

Assembly

- High-Flex 6-head placement machine with a maximum placement rate of approx. 15,000 components per hour and up to 120 different components at the same time

- Chip 0201, LED, QFP, SOP, PLCC, BGA, CSP

- Sockets and connector strips with a size of 35.0 x 35.0 mm and max. Component height of 20.0 mm

- PCB thicknesses from 0.5 mm (min.) To 3.0 mm (max.) And a total panel size of 100.0 x 70.0 mm (min.) Up to 370.0 x 215.0 mm (max.)

- Experience with embedded parts

Reflow Soldering

- 7-zone reflow oven

THT Assembly

- Manual assembly and manual soldering of all common THT components, as well as common and customer-specific cable sets

- Assembly of assemblies in housings

- Visual inspection of assemblies based on the placement plan / IPC rules

- Sealing and painting

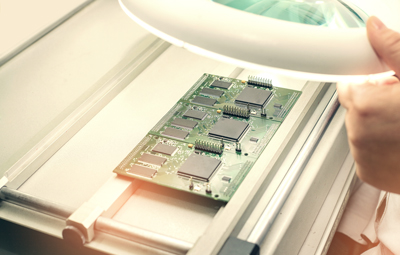

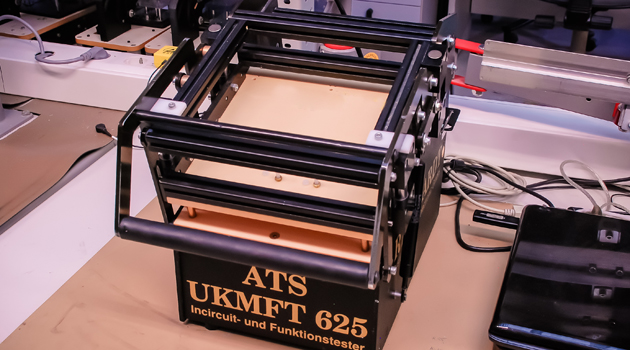

Test

- Voltage of max. 100 V / max. 100 amperes at a power of 3 KW can be tested

- ICT exam

- Conception and implementation of customer-specific tests possible