Development

Our extensive vertical integration empowers us with a significant degree of autonomy, fostering enhanced agility and expeditiousness in delivering cutting-edge products. This capability enables us to swiftly and adaptably construct prototypes, eliminating the need for external dependencies. Furthermore, it allows us to cultivate distinctive expertise in our processes.

We prioritize instilling a profound commitment to quality among our staff. Only through this dedication can quality be cultivated at every individual stage of our operations. We also insist upon this same commitment from our suppliers, who furnish us with top-tier raw materials, including potent magnets, heat-resistant winding wires, and meticulously tempered ground shafts.

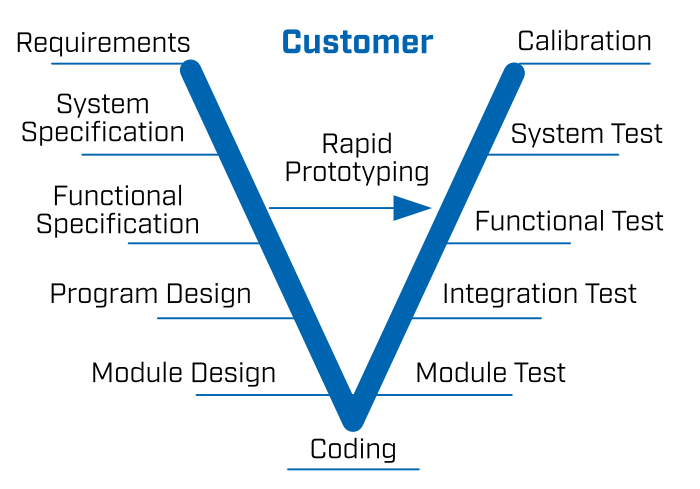

Electric Drive Development

Services

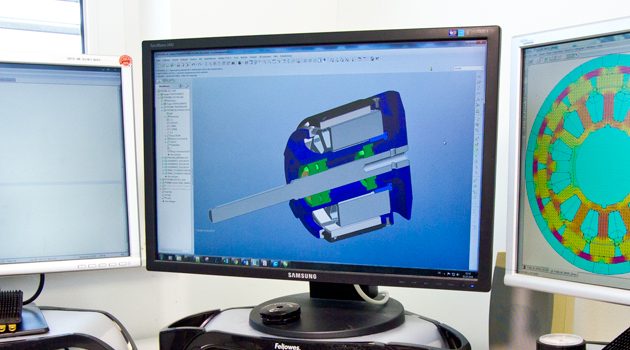

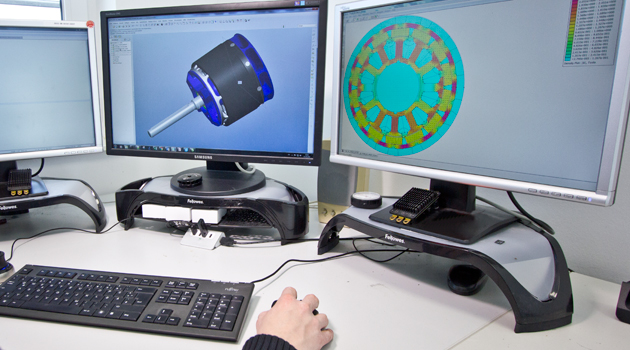

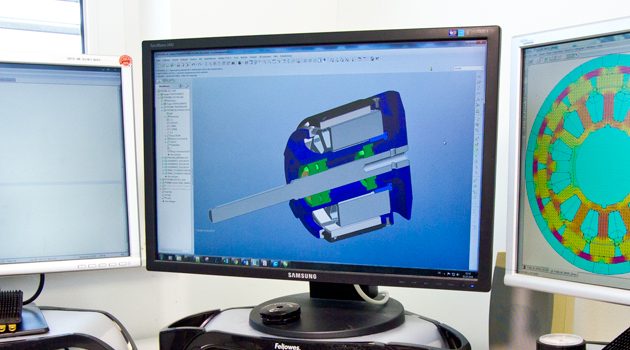

Engine development and drawing with CAD models

Both the construction and the design of the magnetic circuit are carried out in-house by our engine developers.

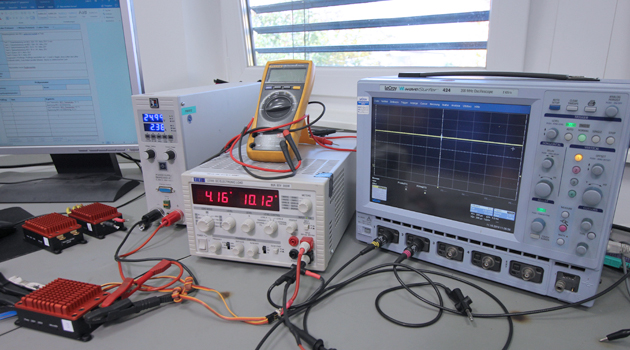

Test stands and test stand construction

With the help of eddy current brakes, microlab boxes, and special test bench structures, we carry out function, performance, and endurance tests.

Milling machines and lathes

We have a well-equipped workshop for engine, fixture and test bench construction

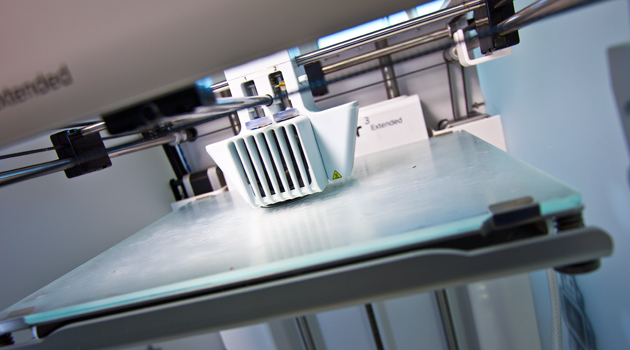

3D printer

Nowadays, a 3D printer should not be missing – irreplaceable if you want to be fast and mobile.

Do you need a customized solution?

Electrictronic Development

Services

Hardware

Software